Specialized Equipment

Flow Bench

Flow Testing Equipment: Our equipment was engineered for the specific purpose of testing carburetors. The "wet flow" machinery was manufactured in the United States during the 1950s and '60s and were used by carburetor manufacturers here in the U.S. Up until the advent of feedback and electronic feedback carburetors, only the machinery's fixtures needed updating. The new electronic carburetors required that feedback processing or signaling be adapted to fit existing machines.

Our flow testing specifications are constantly reinforced in our vehicle service department. Our "wet flow bench test machine" allows the measurable flow rate to be defined on a very minute scale. Even the finest automotive exhaust analyzer available cannot compete with the measuring ability of the "wet flow" machine.

|

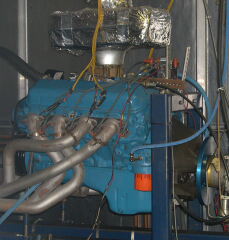

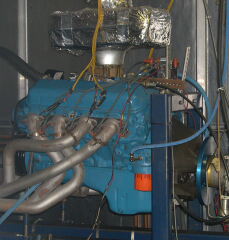

Dynamometer

Dynamometer: A device used to test and measure engines and engine products. We use this primarily to test, calibrate, evaluate, and develop certain carburetors, fuel injectors, fuel systems and engine control systems. Dyno testing is a labor intensive method and therefore is used for research & development as well as special projects. This unit has a computer based data acquisition system which measures torque, exhaust temperatures, fuel flow, air flow (cfm) which in turn calculates horsepower, and brake specific fuel consumption (BSFC) to aid in evaluating efficiency. Air temperature, humidity and barometric pressure are constantly monitored during testing and a correction factor is applied.

* For carburetor and product inventory, visit our store! *

|